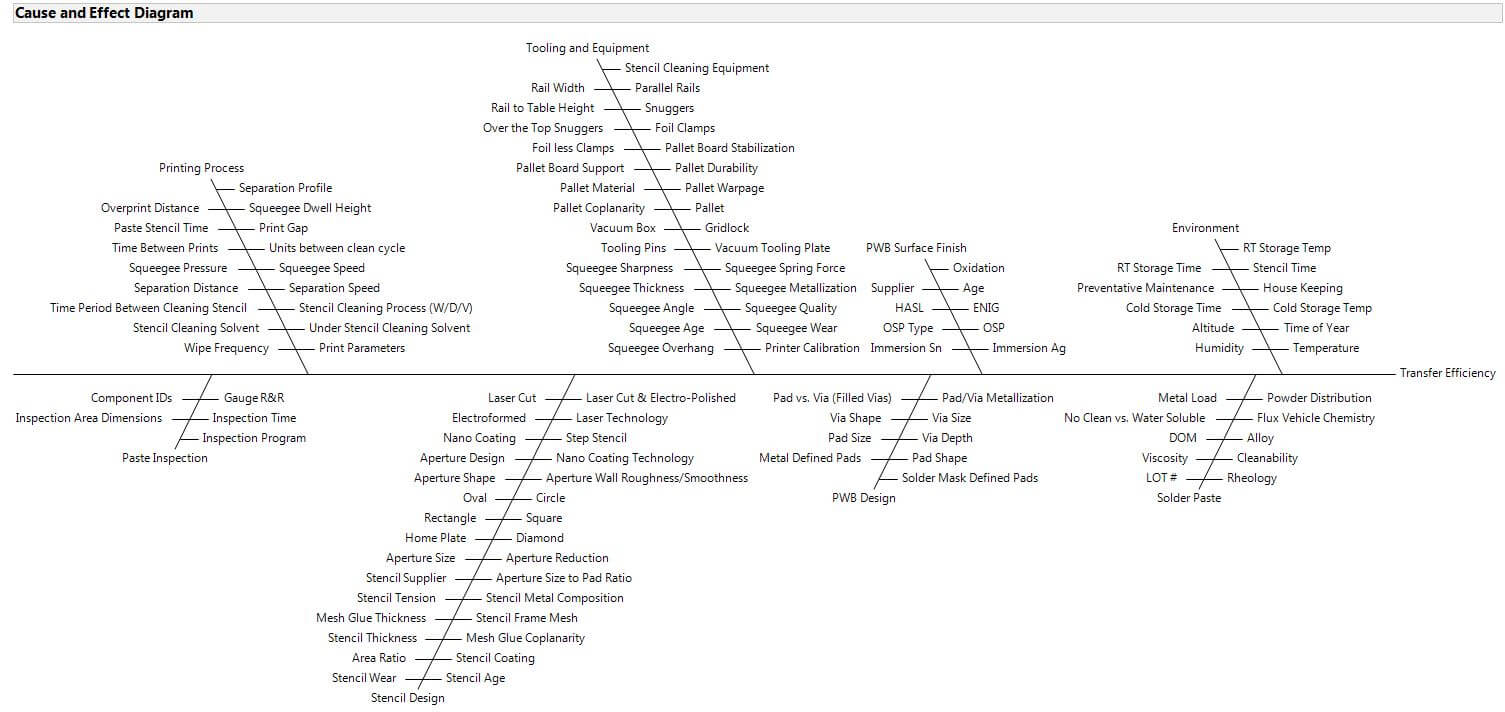

A solder paste's transfer efficiency from the stencil to the PCB board during the printing process is determined by a number of variables. Below is a process diagram listing many of the variables in the printing process that can affect the transfer efficiency.

In my recent conversation with process engineers at an SMT company here in the China, they said one of the critical processes that determine yield in their SMT assembly line is the solder paste printing process.

According to them, one of the key reasons for this is the incorrect printer set-up, which results in issues such as insufficient solder or solder bridging. Of the three elements involved in the process—stencil, solder paste, and printer—the stencil is considered one of the major factors affecting the transfer efficiency, accuracy, and consistency, of solder pastes into the solder pads, especially with the continuing trend towards miniaturization.

Indeed, in our latest survey on solder paste printing, a majority of the respondents highlighted stencils as one of their key challenges. They mentioned the quality of the stencils; getting the right stencils—their stencils are done by a third party; aperture design; and stencil wear, among others, as issues around this part of the process. This is made more challenging because of the finer pitch and spacing in PCB designs. Specific problems in this regard include complete filling of apertures, paste release, and the large range of component types and sizes and the solder paste thickness requirement on the same design.

Other main issues include the accuracy and repeatability of the equipment, and the characteristics of the solder pastes being used.

Which brings me to our topic for this month’s issue of SMT Magazine. Many studies over the years have found that up to 70% of PCB assembly defects come from the solder paste printing operation. In this issue, we look at the critical issues in the solder paste printing process, and how assemblers can address these challenges to help improve their yield and quality.

The paste printing process accounts for the majority of assembly defects, and most defects originate from poor understanding of the effect of printing process parameters on the printing performance.

As the current product miniaturisation trend continues, area array type package solutions are now being designed into products. The assembly of these devices requires the printing of very small solder paste deposits.

The printing of solder pastes through small stencil apertures typically results in stencil clogging and incomplete transfer of paste to the PCB pads. At the very narrow aperture sizes required for flip?chip applications, the paste rheology becomes crucial for consistent paste withdrawal.

This is because, for smaller paste volumes, surface tension effects become dominant over viscous flow. Proper understanding of the effect of the key material, equipment and process parameters, and their interactions, is crucial for achieving high print yields.

During the aperture filling and emptying sub?process, the solder paste experiences forces/stresses as it interacts with the stencil aperture walls and the pad surfaces, which directly impact the paste flow within the apertures. As the substrate and stencil separate, the frictional/adhesive force on the stencil walls competes directly with the adhesives/pull force on the PCB pads, often resulting in incomplete paste transfer or skipping/clogged apertures.

In this paper, we investigate the effect of stencil design on the printing process and in particular the effect on paste transfer efficiency.

Efficient Technology Co., Ltd provide a full SMT assembly line solutions, including SMT Assembly Line, Pick and place machine, Insert Plug-in machine, SMT Reflow oven, Wave Soldering Machine, SMT Stencil Printer, SMT Inspection machine, SMT Peripheral Equipment, SMT Spare Parts etc any kind SMT machines you may need, please Contact us for more information: wechat:+86 13714564591, Skype:sales@effsmt.com, Email: sales@effsmt.com

Contact: Jacky

Phone: +8613714564591

E-mail: sales@effsmt.com

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen