FUJI SMT Screen Printer GPX series

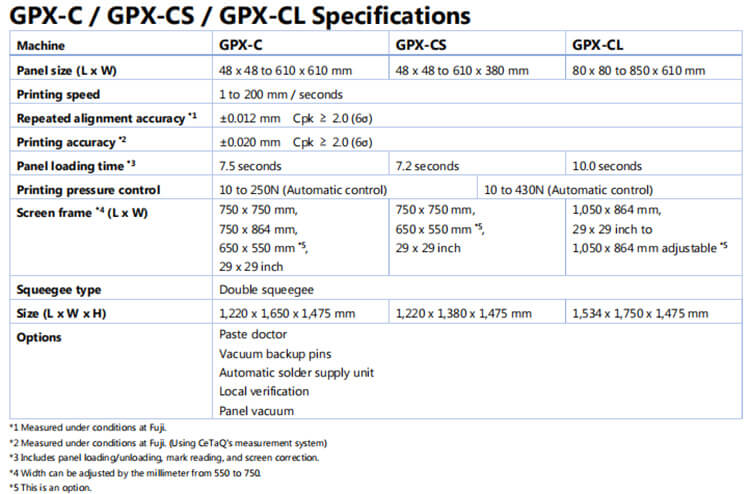

Production range:610x610mm

Printing accuracy:±0.020 mm @6σ (CPK ≥ 2.0)

Weight:1600KG

Dimension:L1220 x W1650 x H1475mm

FUJI SMT Screen Printer GPX series

FUJI SMT Screen Printer GPX series

FUJI Screen Printer GPX series machines provide a complete printing solution that combines superb cost performance with excellent printing accuracy, speed, and usability.

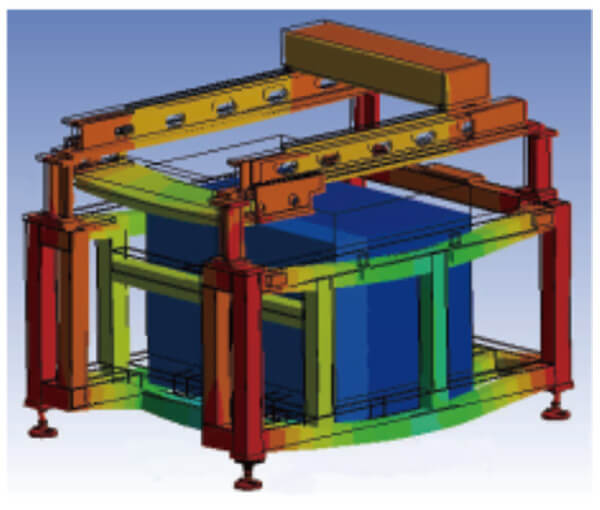

Maintaining alignment accuracy

Consistent highly rigid machine design from the base to printing section enables high accuracy printing for any task - from ultra fine patterns (0201 [008004"] parts) to the printing of large panels - and the durability to maintain printing quality.

High accuracy printing control

By having a load cell ready to use at the machine, printing pressure on the uneven sections of panels and masks can be controlled in real time. The optimum amount of solder filling is always achieved, even when using heavy or long squeegees with which it is difficult to fill evenly.

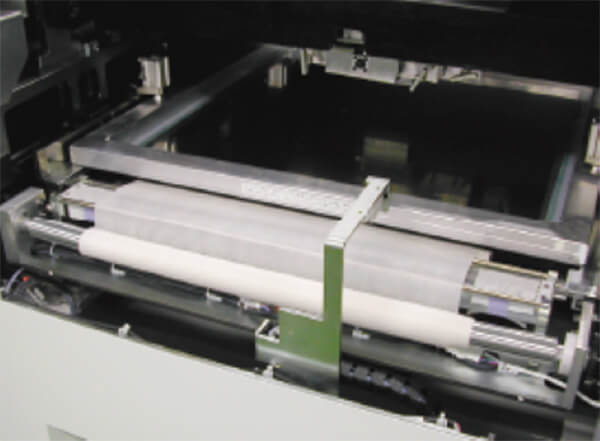

Minimizes maintenance

With a combined wet and dry mechanism that keeps operation to a minimum, these printers significantly reduce cleaning time.

The range in which cleaning fluid is applied is automatically adjusted to match the width of the panel. Only the amount of fluid needed is used, for effective cleaning.

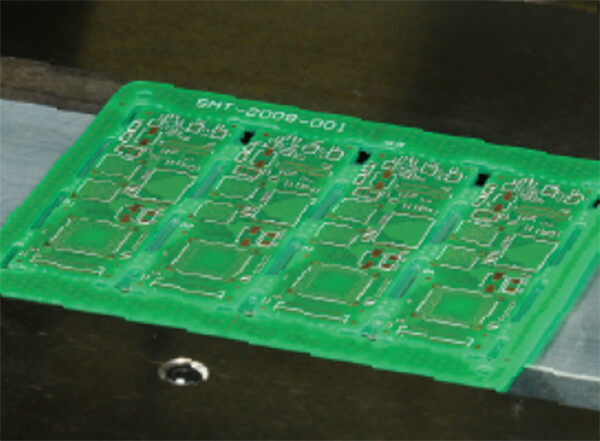

Clamping mechanism supports various types of panels

Stable clamping is achieved by using hybrid clamping, which allows users to select the optimum clamping method (side clamp/top clamp/ edge clamp) according to the characteristics of the panel.

※This is an option on GPX-C II and GPX-CS II

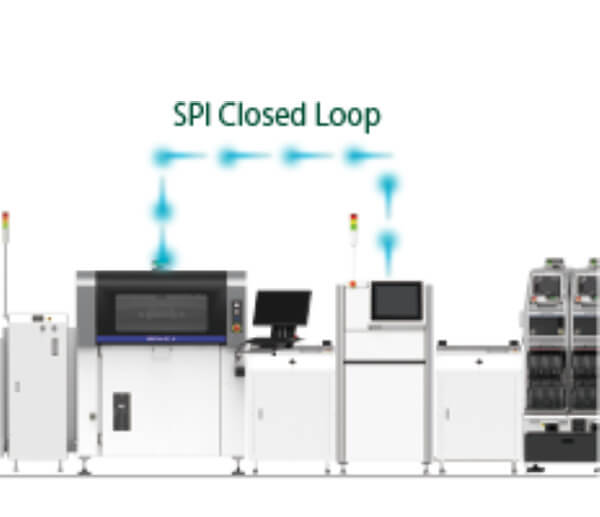

No line stops for quality-related errors

Based on inspection result feedback from SPI machines, future printing problems such as solder volume deviations, misalignment, and smearing can be predicted before they occur. Adjustment of print conditions and cleaning are performed automatically, to constantly maintain high quality printing.

※Option

Various support software available

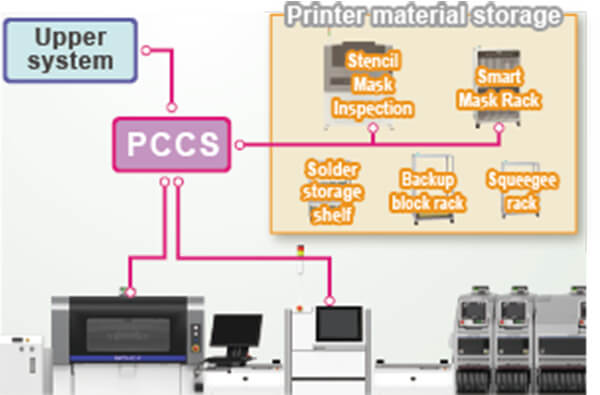

The Printer Central Control System comprehensively collects and manages the necessary production information.

Production is monitored in real time, making it possible to predict the replacement timing for materials and consumable parts. Production programs can be created and transmitted offline, and the system issues guidance for batch checkout and allocation of materials during changeover.

※Option

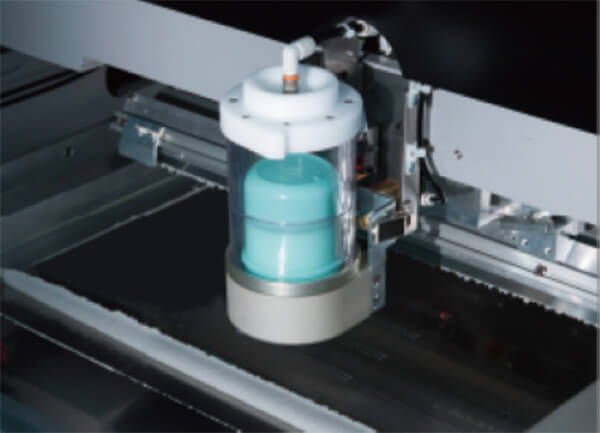

Cup type auto solder supply

The amount of solder is detected, and solder is automatically supplied when necessary. This makes it possible to always print with the appropriate amount of solder, for stable print quality. Work can be completed without mistakes in a short time by using a solder cup as is.

※Option

• Supports dual lanes in a compact body

GPX-CSII is compact model that maintains the basic features of GPX-CII, and is suitable for dual lane production in smaller space.

• Support for extra-large panels

GPX-CL maintains the basic features of GPX-CII while supporting production of even larger panels. With a maximum panel size of 850 x 610 mm, this printer is well suited to production of the large panels used for 5G base stations and servers.

Keywords:

SMT Stencil printer, Automatic SMT solder paste printer, SMT printing machine, SMT PCB printer, GKG stencil printer, GKG printer, 600mm Solder paste printer, 1200mm solder paste printer, Solder paste printer, Panasonic SMT Stencil Printer, JUKI Solder Paste Printer, DEK Stencil printer, Semi-Auto SMT stencil printer Manufacturer.

Efficient Technology Co., Ltd provide a full SMT assembly line solutions, including SMT Assembly Line, Pick and place machine, Insert Plug-in machine, SMT Reflow oven, Wave Soldering Machine, SMT Stencil Printer, SMT Inspection machine, SMT Peripheral Equipment, SMT Spare Parts etc any kind SMT machines you may need, please Contact us for more information: Wechat : +86 13714564591, Skype : sales@effsmt.com, Email : sales@effsmt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / phone /Wechat online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

Contact: Jacky

Phone:

E-mail: sales@effsmt.com

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen