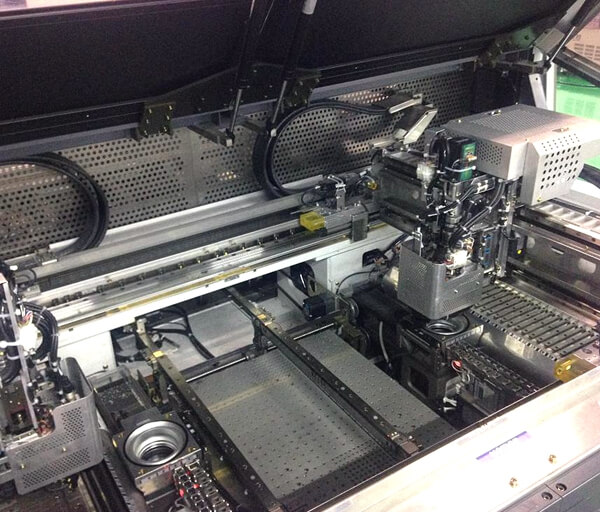

Hitachi GXH-1S Pick and Place Machine

High production

Real-life performance

Component range: 0201 ~ 44 * 44mm

Product description: Hitachi GXH-1S Pick and Place Machine, Real-life performance, Component range: 0201 ~ 44 * 44mm

Hitachi GXH-1S Pick and Place Machine

Hitachi GXH-1S Pick and Place Machine

Two independent work cells (stages) allow simultaneous assembly of two boards.

All X and Y axes are operated by linear motors.

Each Y axis has two motors for enhanced stability and repeatibility.

Four placement heads have up to 12 nozzles each.

On-the-fly recognition of all components.

A line sensor on each head checks for component presence, orientation, and correct thickness.

Unique board conveyor system moves both rails for optimum board postioning during production.

No more "fixed rails"

Hitachi GXH-1S parameters

High precision long life decomposition energy: 0.0048um, speed: 2m / sec maximum acceleration of 3G.

Dress accuracy: +/- 0.05mm, special correction: +/- 0.035mm

12 nozzles, 12 parts as long as the shuttle flash once know, Camera recognition time, 2m / s,

Large field of view 0201 ~ 44 * 44mm parts are recognized once, up to 55 * 55mm

connect to 100 * 26 * 25.4mm

Walking flash understanding, high-brightness lighting, awareness correction, video capture time: 5u / sec

The use of a double hanging material feeder can fly two different materials can be linked to

high-speed high-precision feeding, driven by a servo motor,

speed: 0.08 seconds / a (feeding pitch is 2,4mm)

Accuracy: +/- 0.05mm (8mm * 2mmpitch 0201)

Feeder models of simplification, paper, tape for feeding, feed pitch variable

A head has 12 suction nozzles, a nozzle automatically replace the system, each line when the actual production needs change, the system automatically replace the nozzle,

the change line faster, (production does not replace the nozzle)

Heterosexual head 3 nozzle is in the production according to the size of the parts to replace the nozzle

Double track within the device, the same table can be placed two boards (circuit board width below 215mm)

Part Database Automatically builds new part data for your system in just 1-5 minutes

Widely used high-speed placement head 0402 ~ □ 44mm

High-speed / multi-functional placement head non-stop replacement placement head module

Smart Tape Feeder / Multi-Layer Tray Feeder with Non-Stop Feeder Module

High production

Real-life performance and stability of the direct drive placement head

Linear motor drive 4-axis 4-head structure; non-stop one-time identification (up to 12 parts)

Keywords:

SMT pick and place machine, Hanwha HM520 Plus Pick and Place Machine, Hanwha DECAN S2 Pick and Place Machine, JUKI RS-1R Chip Mounter, JUKI RX-8 pick and place machine, Yamaha Z-TA-R YSM40R Pick and Place Machine, Hanwha Chip Mounter, JUKI Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Efficient Technology Co., Ltd provide a full SMT assembly line solutions, including SMT Assembly Line, Pick and place machine, Insert Plug-in machine, SMT Reflow oven, Wave Soldering Machine, SMT Stencil Printer, SMT Inspection machine, SMT Peripheral Equipment, SMT Spare Parts etc any kind SMT machines you may need, please Contact us for more information: Wechat : +86 13714564591, Skype : sales@effsmt.com, Email : sales@effsmt.com

Contact: Jacky

Phone: +8613714564591

E-mail: sales@effsmt.com

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen