Feeder storage Cart

Panasonic Feeder storage Cart

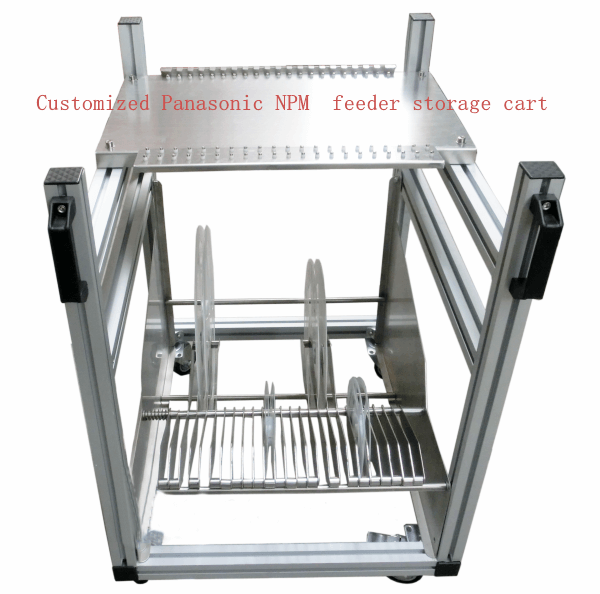

Panasonic Customized NPM feeder storage cart

Usage:Panasonic pick and place machine

Product description: Panasonic Customized NPM feeder storage cart

Panasonic Customized NPM feeder storage cart

Panasonic Customized NPM feeder storage cart

40PCS/LAYER, 2 LAYERS

Length 1000MM *Width 700MM * Height 1110MM

Castors :Four metal flexible castors

About 30 kg.

Description:

1.Suitable for SMT workshop feeder placed, prepare feeder materials ahead of time, improve production efficiency.

2.Stainless steel welding whole, frame will never be out of shape.

1.The main use of 30*30MM stainless steel

2. With four universal casters ( two of them with brake ), anti static chain Each

3. Layer may be placed 40 pcs 8MM feeder

4. Appearance specifications: 800x600x1100mm

5 Roots of the customer requirements for customized feeder placed cart

Uses: For placing feeder,feeder preparation in advance,Feeder Turnover store,Increase productivity.

Widely used in SMT production workshop feeder turnover and placement,place smoothly,freedomto take put,random move or fixed.

Material: Using stainless steel material,architecture designed with high hardness square pass,the cart body is light and strong,durable.Four 3-inch casters,two with brake,two activities,convenient to move;

Quality: Using the advanced welding technology welding,replace the traditional manual welding,Cut fine,welding without welding,neat,no burr,after filled feeder the frame is not deformed,the whole firm,lightweight, strong, durable;

Technology:

Steel die punch made feeder positioning plate, and have the same principle with SMT

FEEDER platform placed , to achieve a perfect position, the top use large circular, to avoid an acute angle, the design is divided into upper and lower two layers, after installed feeder solid appearance, with a grounding chain, effective anti-static;

Feeder car features:Feeder car made of stainless steel processing, the body strong, lightweight, durable, flexible, overall feeder placement platform are used manual welding processes , install anti-static towline can be moved with brakes. Upper and lower levels, can be loaded with a total of 80 feeder.

Widely used in SMT production workshop FEEDER turnover and placement, placement stable,

to take place freely, greatly increasing the work productivity. Are made of stainless steel and aluminum production.

Storage quantity: total two layers, each placed 40 feeder, can put a total of 80 feeder.

Keywords:

Samsung Feeder Storage Cart, Hanwha Feeder Storage Cart, Yamaha Feeder Storage Cart, SMT Feeder storage Cart, Juki Feeder Storage Cart, Panasonic Feeder storage Cart, Pick and place machine Feeder storage Cart, Seimens Feeder storage Cart, FUJI Feeder storage Cart, JUKI Feeder storage Cart, Hitachi Feeder storage Cart, I-Pulse Feeder storage Cart, SMT PCB Storage Cart, PCB Tray Cart.

Efficient Technology Co., Ltd provide a full SMT assembly line solutions, including SMT Assembly Line, Pick and place machine, Insert Plug-in machine, SMT Reflow oven, Wave Soldering Machine, SMT Stencil Printer, SMT Inspection machine, SMT Peripheral Equipment, SMT Spare Parts etc any kind SMT machines you may need, please Contact us for more information: Wechat : +86 13714564591, Skype : sales@effsmt.com, Email : sales@effsmt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / phone /Wechat online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

Contact: Jacky

Phone: +8613714564591

E-mail: sales@effsmt.com

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen