Dimension:870*1040*1300 mm

Max PCB Size:330x480mm

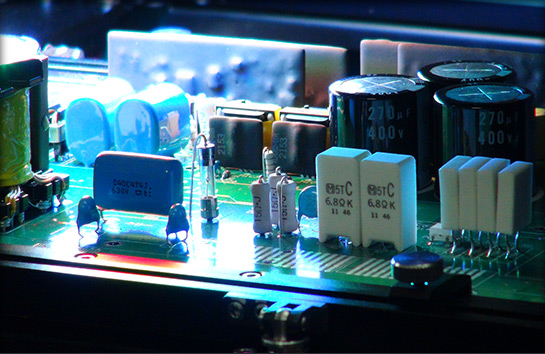

Inspection Component: 0201 chip

Weight:Aprox. 360kg

Product description: SMT AOI Machine Offline A410,Dimension:870*1040*1300 mm,Max PCB Size:330x480mm,Inspection Component: 0201 chip,Weight:Aprox. 360kg

SMT AOI Machine Offline A410

Easy to operate and multi-function AOI

Different AOI model can be placed at several quality controlling points in SMT line such as to check 2D paste printing quality, check component defects before reflow soldering, check PCBA quality after reflow soldering, and DIP after wave soldering.

Multi-algorithms and techniques

Novel structure and tight security;

Simple programming and debug mode, easy to operate;

Automatically identify PCB, and automatically identify if the board is put on 180° reverse side;

Simultaneous inspection for multi-boards and inspection shift of 2 sides of board (components top and bottom) improves the inspection efficiency;

Smart camera barcodes identify system. (The camera can identify single-dimensional barcode and data matrix barcode);

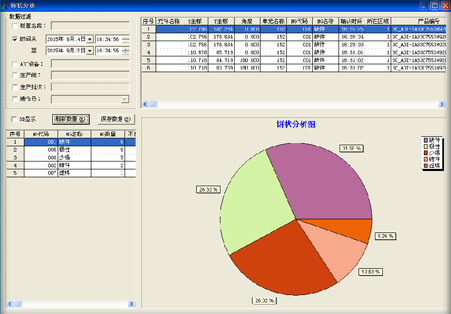

Professional SPC analysis system, monitoring and analysis the quality of products in real time;

Multiple machine monitoring system, can know well of all production lines’ condition;

Remote programming and debugging make the software is more easy and convent.

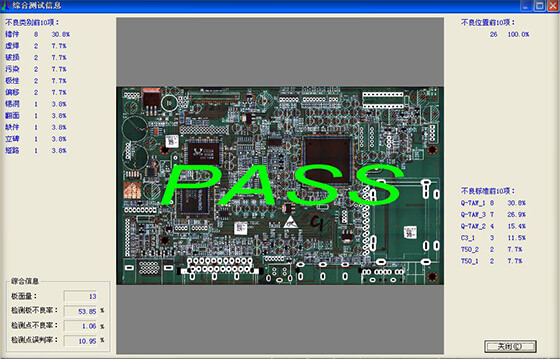

Simple test results report

The test report contains some contents of SPC, according to the real test case shows the ratio of NG and distribution, real-time show the quantity of the testing boards 、parts per million 、false-positive rate and other relevant information, so the operator is easy to know the detail of the production line.

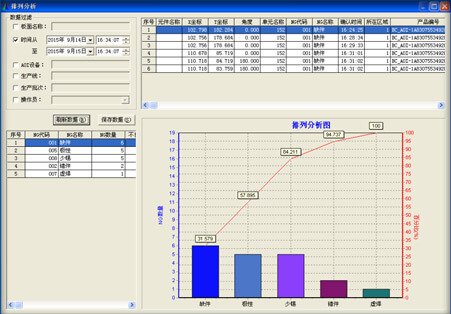

Professional SPC system

Professional SPC analysis report to macroscopic readjustment and control the production line, reduce the incidence and raise produce Efficiency.

Inspection System & Optical System

Inspection Object | Skew / Tombstone / Wrong part / Missing / Overturning / Damaged / |

Inspection Component | 0201 chip , IC pin(0.3mm pitch), wave solder |

Inspection Method | Full color image statistic analysis, OCP, IC bridge analysis, color linear analysis color non-linear analysis, similarity analysis, black-white ratio analysis, intensity analysis |

Camera | Color CCD (1.45MPa Pixels), Resolution 20um, FOV 20*20mm (customized), speed:2000mm²/s |

Light Source | RGB Ring Multi-angle LED combination lighting, high brightness, standard CCTV lens, DOV 2mm |

Software & Computer

Computer | CPU: Dual-core 2.7G, RAM: DDRIII-2G hard disk : 120G, 22" wide screen LCD |

Mechanical System

PCB Thickness | 0.3 - 5.0 (PCB Warpage < 5mm) |

PCB Width | 25x25-330x480mm (can be customized) |

Driving Method | AC Servo Motor+ball screw rod+linear guide rail |

Motion Speed | Max 700mm/s |

PCB Clamp | Automatic |

Power | AC220V / 50Hz, UPS 1000W |

Dimension | 870*1040*1300 mm |

Weight | Aprox. 360kg |

Off line AOI Inspection machine Future:

1. HD image, easy for 0201 chip.

2. Full color image statistics analysis

3. Optical character recognition(OCR)

4. IC bridge analysis

5. Color analysis

6. Graphics similarity

7. Black white ratio analysis

8. Intensity analysis

9. Non linear color analysis

10. CAD data input and output

11. MPF technology, fast programming

12. Camera barcode identification(1D&2D)

13. Spare component library

14. Auto double side test

15. Auto skip test

16. SPC

17. Off line inspection system

18. NG Rate<99%, Repeat accuracy<3 pcs, False Negative<10PPM, False Positive<5000PPM.

Keywords:

SMT Inspection Machine, SMT AOI Machine, Offline AOI Machine, Online AOI Machine, SMT X Ray Machine, SMT SPI Machine, Offline SPI Machine, In line SPI Machine, 3D SPI Machine, 3D AOI Machine, Solder Paste Inspection Machine, Koh Young SPI/AOI, JUKI AOI/SPI, SAKI AOI, Omron SPI/AOI.

Efficient Technology Co., Ltd provide a full SMT assembly line solutions, including SMT Assembly Line, Pick and place machine, Insert Plug-in machine, SMT Reflow oven, Wave Soldering Machine, SMT Stencil Printer, SMT Inspection machine, SMT Peripheral Equipment, SMT Spare Parts etc any kind SMT machines you may need, please Contact us for more information: Wechat : +86 13714564591, Skype : sales@effsmt.com, Email : sales@effsmt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / phone /Wechat online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

Contact: Jacky

Phone: +8613714564591

E-mail: sales@effsmt.com

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen