YAMAHA 3D AOI YRi-V

Super high-speed 3D inspections 56.8cm²/sec (under optimum conditions)

Super high-accuracy 3D inspections 8-way projector

4-way oblique imaging inspections 20Megapixels 4-angle camera

Device inspections Super high-resolution 5μm/coaxial lighting

YAMAHA 3D AOI YRi-V

Multi-purpose optical inspection systems for all markets that realize super high-speed and high-accuracy 3D inspections. The mounted coaxial lighting and 5μm lenses added to the lineup support high-accuracy inspections in the device sector.

The newly developed high-performance inspection head significantly improve the inspection performance of the 2D inspections, 3D inspections, and 4-angle cameras. The inspection performance can be applied to all SMT sectors.

Yamaha’s proprietary high-rigidity frame realizes high-accuracy and super high-speed inspections. The inspection speed is 1.6 to 2.0 times as before, which supports inspections in mass-production.

8-way projector / 4-way projector(select)

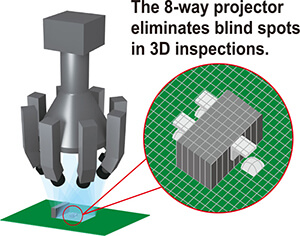

The 8-way projector added to the lineup has enabled inspecting 0201mm components mounted adjacently. The projector reduces the number of blind spots for large components, realizing high-accuracy 3D inspections. The increased 3D measurement range enables 3D inspections of components with heights of up to 25mm.

The 8-way projector added to the lineup has enabled inspecting 0201mm components mounted adjacently. The projector reduces the number of blind spots for large components, realizing high-accuracy 3D inspections. The increased 3D measurement range enables 3D inspections of components with heights of up to 25mm.

20Megapixels high-resolution cameras were adopted. Clear images enable accurate secondary judgment. The higher picture quality improves the accuracy of automatic inspections based on oblique images.

20Megapixels high-resolution cameras were adopted. Clear images enable accurate secondary judgment. The higher picture quality improves the accuracy of automatic inspections based on oblique images.

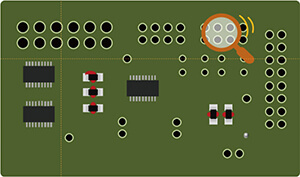

New inspection functions required in the inspection process in the device sector were developed. Capable of detecting minute problems such as cracks and chips on semiconductor components (e.g., wafers and WLCSPs), contributing to improving the quality of device products.

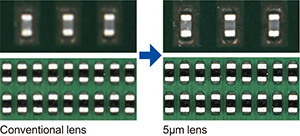

The 5μm lenses added to the lineup are capable of higher definition inspections compared to the conventional 7μm lenses. The lenses improve the performance of high-accuracy inspections of super-tiny components (e.g., 0201mm components) and inspections of minute problems such as cracks and chips on components.

The 5μm lenses added to the lineup are capable of higher definition inspections compared to the conventional 7μm lenses. The lenses improve the performance of high-accuracy inspections of super-tiny components (e.g., 0201mm components) and inspections of minute problems such as cracks and chips on components.

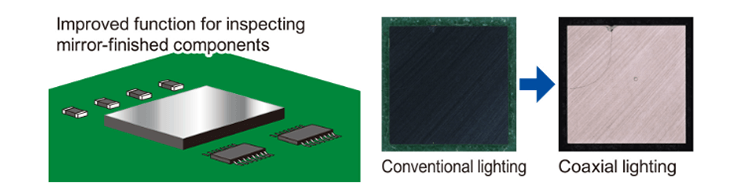

For accurate inspection of the surface of mirror-finished components, coaxial lighting was added to the Yamaha’s proprietary 3-step white dome-shaped lighting. The system for which the inspection performance required in the device sector was improved takes images of the surface of semiconductor components (e.g., wafers and WLCSPs) clearly.

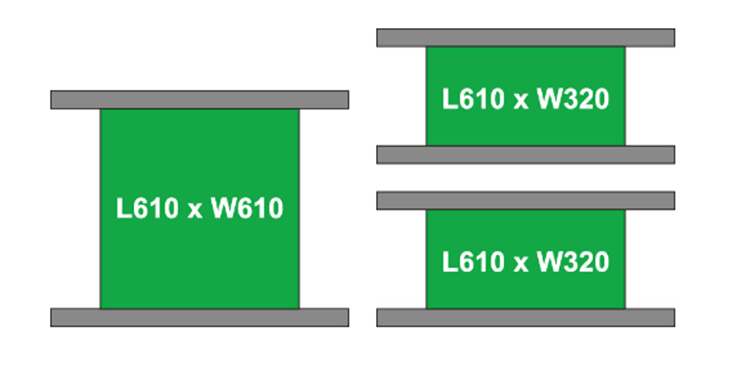

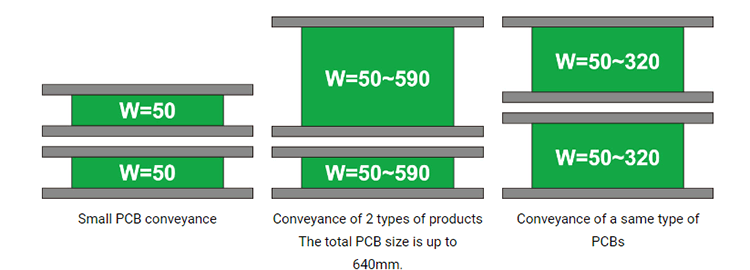

YRi-V can handle large PCBs with L610mm and W610mm as a standard. The dual lane system can convey large PCBs with W320mm on the two lanes.

The newly developed dual lane system can operate each lane flexibly. The system that can be easily connected to upstream and downstream equipment contributes to establishing dual-lane lines flexibly.

New easy-to-see operation screens with advanced design were adopted. New functions mounted make it possible to create data in a simple way.

New easy-to-see operation screens with advanced design were adopted. New functions mounted make it possible to create data in a simple way.

Inferior images are sent to the operator’s mobile unit via a wireless LAN, which makes it possible to judge pass or fail remotely. The system allows line operators to also make decisions, contributing to labor savings.

The system can directly convert all types of data (e.g., CAD, CAM, and mounter data) into inspection data and automatically creates PCB images from Gerber data. The system detects through holes on DIP PCBs automatically and can create inspection data automatically.

AI automatically identifies the component types based on images taken by the camera and applies the optimum component library automatically, contributing to simplifying the inspection data creation.

YRi-V | |||

Applicable PCB | L610 × W610mm (max.) to L50 × W50mm (min.) (single lane) | ||

L750mm long length PCBs available (option) | |||

PCB height that can be carried in | Top : 45mm, bottom : 85mm (single lane) | ||

Maximum 3D measurement height | 25mm | ||

Number of pixels | 12Megapixels | ||

Number of pixels of | 20Megapixels | ||

the 4-angle camera | |||

3D inspection speed | 12μm resolution | 7μm resolution | 5μm resolution |

(under optimum conditions) | |||

4-projection | 56.8cm²/s | 19.6cm²/s | 10.1cm²/s |

External dimension | L1,252 x W1,497 x H1,614mm | ||

(except the protrusions) | |||

Weight | 1,480kg | ||

Keywords:

SMT Inspection Machine, SMT AOI Machine, Offline AOI Machine, Online AOI Machine, SMT X Ray Machine, SMT SPI Machine, Offline SPI Machine, In line SPI Machine, 3D SPI Machine, 3D AOI Machine, Solder Paste Inspection Machine, Koh Young SPI/AOI, JUKI AOI/SPI, SAKI AOI, Omron SPI/AOI.

Efficient Technology Co., Ltd provide a full SMT assembly line solutions, including SMT Assembly Line, Pick and place machine, Insert Plug-in machine, SMT Reflow oven, Wave Soldering Machine, SMT Stencil Printer, SMT Inspection machine, SMT Peripheral Equipment, SMT Spare Parts etc any kind SMT machines you may need, please Contact us for more information: Wechat : +86 13714564591, Skype : sales@effsmt.com, Email : sales@effsmt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / phone /Wechat online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

Contact: Jacky

Phone:

E-mail: sales@effsmt.com

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen