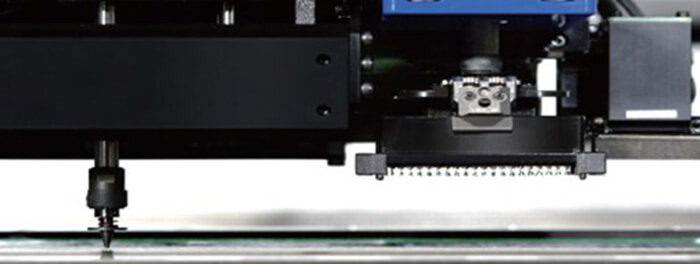

Hanwha SM485P Chip Mounter is a multifunctional Hybrid Mounter. In addition to SMD components, it can quickly and reliably mount various plug-in components and special-shaped components.

Placement speed: 12,000 CPH (Optimum)

Machine dimension: 1650*1679*1993mm

Weight: Approx 1600kg

Hanwha SM485P Hybrid Pick and Place Machine

Hanwha SM485P Hybrid Pick and Place Machine

Smart Hybrid Hanwha SM485P is based on the platform of the high-speed chip mounter SM485, which strengthens the ability to respond to special-shaped components. It is equipped with a general-purpose machine with 1 cantilever and 4 shafts. It can mount ICs up to 55mm and supports Polygon identification solutions. , and provide the optimal solution for special-shaped components with complex shapes. In addition, by applying the electric feeder, the actual productivity and placement quality have been improved. Moreover, it can be shared with SM pneumatic feeder, which maximizes the convenience of customers.

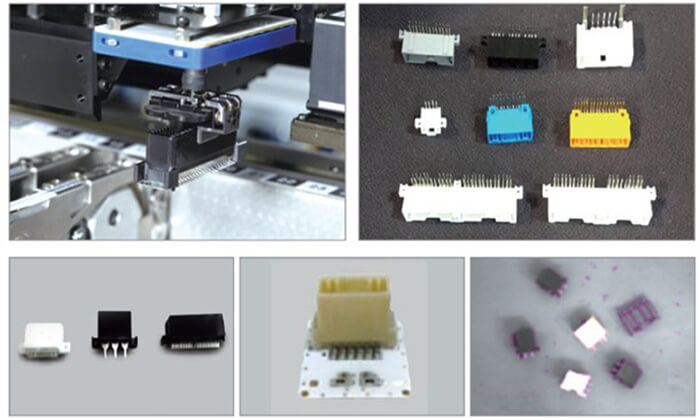

Reliable Insertion & Verification Solutions

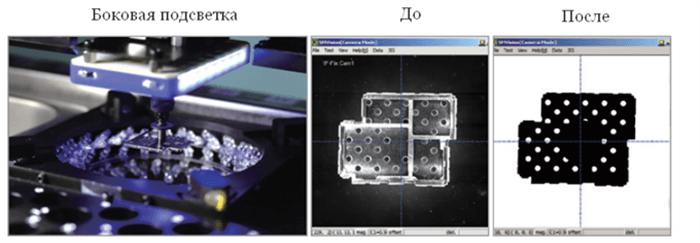

Laser Light: Through the four-way laser lighting on the Wide Camera, the identification of individual Lead Pins of plug-in components is enhanced.

Laser Light For Small Camera (Option): It can identify the lead pins of small and medium-sized plug-in components by using laser illumination through the small camera, and can simultaneously inspect and mount each pin of Max 22mm.

Back Light: It can accurately identify scattering and translucent components. (Ex: Shield can, Lens, Tape, etc.).

Height Sensor (Option): After the components are mounted, use the Sensor to measure the height, which can detect missing / lifted / poor insertion of components in real time.

High Productivity & Special Process Solutions

4 Precision Sindle Head (P4 Head): The front is equipped with 4 cameras as standard, which can recognize and place 4 small and medium-sized components at the same time.

Dual Fix Camera (Option): When the Dual Fix Camera is loaded on the back, it can identify and place two medium and large components at the same time.

Solutions for special process/special-shaped components:

1. Set insertion/mounting pressure (Force Control): 0.5~50N

2. Large/long component MFOV (segmentation identification): 2/3/4 division

3. Support Gripper for plug-in components: ~Max H42mm

Large component supply device: can supply medium and large components (Tray Size: 420*350mm)

Key Features:

The machine is equipped with 5 heads - 4 high-speed, 1 high-precision with pressure control.

Possibility of installing any non-standard components using a mechanical gripper (gripper) and pressure control.

Possibility of using different lights for recognition. Backlit for improved shadow recognition. Laser illumination for improved recognition of pins and legs.

Keywords:

Hanwha Insert Plug-in machine, JUKI Insert Plug-in machine, Yamaha Insert Plug-in machine, Panasonic Insert Plug-in machine, Hybrid Modular Surface Mounter, Hybrid Placement Machine, Insert Plug-in machine, Offline Insert Plug-in machine, Inline Insert Plug-in machine, Vertical Plug-in machine, Horizontal Plug-in machine, Heterotypic Plug-in machine.

Efficient Technology Co., Ltd provide a full SMT assembly line solutions, including SMT Assembly Line, Pick and place machine, Insert Plug-in machine, SMT Reflow oven, Wave Soldering Machine, SMT Stencil Printer, SMT Inspection machine, SMT Peripheral Equipment, SMT Spare Parts etc any kind SMT machines you may need, please Contact us for more information: Wechat : +86 13714564591, Skype : sales@effsmt.com, Email : sales@effsmt.com

Contact: Jacky

Phone:

E-mail: sales@effsmt.com

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen